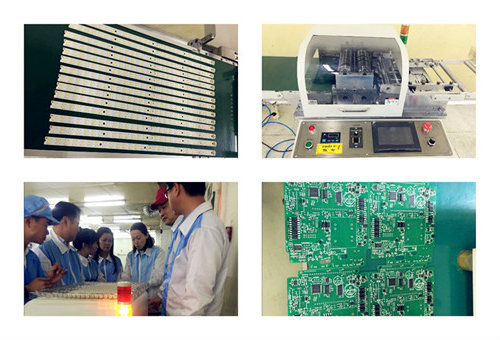

Features:

? The machine adopts the computer screen control with a counting device, which you can use

to preset the processing production. And the space of cutting tool is visible on the screen.

? It can cut many boards with multiple sets of knives work at the same time.

? The knife flywheel is adjustable as a whole from 0 to 5mm

? The distance between knives is regulable as well, applying to pcb with width from

15mm to 20mm.

? The blade is made of imported SKH51 high speed steel material, which is durable and

have a long service life.

? It is convenient to adjust the cutting speed through rotary knob.

? No limits of the cutting length.

? Thickness range of pcb: 0.2-5.0mm

? With a conveyor belt line, the separated pcb can be send out directly to reduce pick- and-place.

? The machine adopts multiple blade to separate boards with simple operation and

high efficiency, fitted for batch production.

Specification:-We were looking for PCB de-paneling machine to separate final assembled pre V-Groove boards-YSVC-650

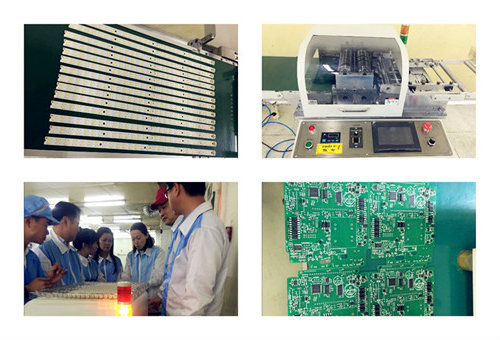

Features:

? The machine adopts the computer screen control with a counting device, which you can use

to preset the processing production. And the space of cutting tool is visible on the screen.

? It can cut many boards with multiple sets of knives work at the same time.

? The knife flywheel is adjustable as a whole from 0 to 5mm

? The distance between knives is regulable as well, applying to pcb with width from

15mm to 20mm.

? The blade is made of imported SKH51 high speed steel material, which is durable and

have a long service life.

? It is convenient to adjust the cutting speed through rotary knob.

? No limits of the cutting length.

? Thickness range of pcb: 0.2-5.0mm

? With a conveyor belt line, the separated pcb can be send out directly to reduce pick- and-place.

? The machine adopts multiple blade to separate boards with simple operation and

high efficiency, fitted for batch production.

Specification:-We were looking for PCB de-paneling machine to separate final assembled pre V-Groove boards-YSVC-650